ASME B16.11 Dimensional Tolerances

Engineering Specifications for Socket Weld Fittings Manufactured Per ASME B16.11-2001   DIMENSIONAL TOLERANCES PERMITTED UNDER THIS AMERICAN STANDARD ASME B16.11-2001 | ||

|---|---|---|

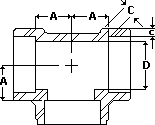

| "A" - CENTER TO BOTTOM OF SOCKET | FOR SIZES 1/8" AND 1/4" | ± 0.03" |

| 3/8", 1/2" AND 3/4" | ± 0.06" | |

| 1", 1-1/4", 1-1/2" AND 2" | ± 0.08" | |

| 2-1/2", 3", AND 4" | ± 0.10" | |

| "B" - BORE DIAMETER OF SOCKET | FOR SIZES 1-1/2" AND SMALLER | + 0.020" - 0.000" |

| 2", 2-1/2", 3" AND 4" | + 0.025" - 0.000" | |

| "C" - SOCKET WALL THICKNESS | MINIMUM = 1.09 T (BUT NOT LESS THAN 5/32") T = WALL THICKNESS OF NOMINAL PIPE | |

| "D" - BORE DIAMETER OF FITTING | FOR SIZES 2" AND SMALLER | ± 0.030" |

| 2-1/2", 3" AND 4" | ± 0.060" | |

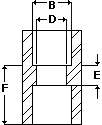

| "E" - BOTTOM TO BOTTOM OF SOCKETS - COUPLINGS | FOR SIZES 1/8" AND 1/4" | ± 0.06" |

| 3/8", 1/2" AND 3/4" | ± 0.12" | |

| 1", 1-1/4", 1-1/2" AND 2" | ± 0.16" | |

| 2-1/2", 3", AND 4" | ± 0.20" | |

| "F" - BOTTOM OF SOCKET TO OPPOSITE FACE - HALF COUPLINGS | FOR SIZES 1/8" AND 1/4" | ± 0.03" |

| 3/8", 1/2" AND 3/4" | ± 0.06" | |

| 1", 1-1/4", 1-1/2" AND 2" | ± 0.08" | |

| 2-1/2", 3", AND 4" | ± 0.10" | |

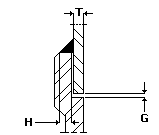

| "G" - WELDING GAP | APPROXIMATELY 0.06" RECOMMENDED GAP BEFORE WELDING | |

| "H" - MINIMUM FLAT | MINIMUM FLAT = 0.75 X MINIMUM SOCKET WALL THICKNESS | |